- View Mobile Number

sales@velinnovative.com

Induction Hardening Services

Leading Manufacturers, Exporters and Wholesaler of Ball Bolt Induction Hardening Service, Brake Drums Induction Hardening Service, Cam Induction Hardening Service, Die Induction Hardening Service, Fasteners Induction Hardening Service, Gear Teeth Induction Hardening Service, Groove Rings Induction Hardening Service, Induction Hardening Service, Induction Heater for Pre and Post Weld Heat Treatment Service, Large Diameter Induction Hardening Rolls Service, Pin Induction Hardening Services, Pinion Induction Hardening Service, Shaft Induction Hardening Service, Smaller Diameter Induction Hardening Roll Service, Sprockets Induction Hardening Service and Wheels Induction Hardening Service from Mumbai.

Ball bolt induction hardening service employs electromagnetic induction to heat the surface of ball bolts, followed by rapid quenching for enhanced properties. This process strengthens the bolts, increasing wear resistance and durability, crucial in automotive, aerospace, and machinery sectors. Selective hardening preserves core toughness and structural integrity. The service significantly improves ball bolt performance and lifespan, ensuring reliable operation under heavy loads and harsh conditions. It's essential for safety, efficiency, and reducing maintenance costs in various industrial applications.

Brake drums induction hardening service employs electromagnetic induction to heat the surface of brake drums, followed by rapid quenching to enhance their properties. This process strengthens the drums, increasing wear resistance and durability, crucial for automotive braking systems. By selectively hardening the surface, the drums maintain their core toughness and structural integrity. This service significantly improves the performance and lifespan of brake drums, ensuring reliable and safe braking in vehicles, contributing to overall road safety and driver confidence.

Cam induction hardening service utilizes electromagnetic induction to heat the surface of cams, followed by rapid quenching to enhance properties. This process strengthens the cams, improving wear resistance and durability, critical in automotive, machinery, and aerospace sectors. Selective hardening preserves core toughness and structural integrity. The service significantly boosts cam performance and lifespan, ensuring reliable operation under heavy loads and harsh conditions. It's vital for maintaining efficiency, reducing downtime, and enhancing the overall reliability of cam systems in various industrial applications.

Die induction hardening service utilizes electromagnetic induction to heat the surface of dies, followed by rapid quenching to enhance their properties. This process strengthens the dies, increasing wear resistance and durability, crucial for precision manufacturing industries like automotive, aerospace, and tooling. By selectively hardening the surface, the dies maintain their core toughness and dimensional accuracy. This service significantly improves the performance and lifespan of dies, ensuring reliable and consistent production processes, ultimately enhancing productivity and product quality.

Fasteners induction hardening service utilizes electromagnetic induction to heat the surface of fasteners, followed by rapid quenching for enhanced properties. This process strengthens fasteners, boosting wear resistance and durability, vital in automotive, aerospace, and manufacturing sectors. Selectively hardening the surface preserves core toughness and structural integrity. The service substantially enhances fastener performance and longevity, ensuring reliable and secure fastening solutions across diverse applications. It's a critical process for meeting stringent quality standards and maintaining safety in various industrial settings.

Gear teeth induction hardening service employs electromagnetic induction to heat the surface of gear teeth, followed by rapid quenching for enhanced properties. This process strengthens gear teeth, increasing wear resistance and durability, crucial in automotive, aerospace, and machinery industries. Selective hardening preserves core toughness and dimensional accuracy. The service significantly improves gear performance and lifespan, ensuring reliable operation under heavy loads and harsh conditions. It's essential for maintaining efficiency, reducing downtime, and enhancing the overall reliability of gear systems.

Groove rings induction hardening service utilizes electromagnetic induction to heat specific sections of groove rings, followed by rapid cooling to enhance their surface properties. This process strengthens the rings, improving their wear resistance and durability, crucial in applications where heavy loads or friction are common, such as automotive transmission components and industrial machinery. By selectively hardening only the grooves, the rings maintain their core toughness. This service significantly extends the lifespan and reliability of groove rings in various mechanical systems.

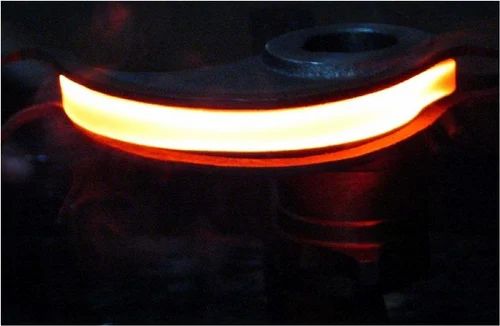

Induction hardening service enhances the surface properties of metal components by rapidly heating them with electromagnetic induction, followed by quenching. This process strengthens the surface, improving wear resistance and durability, crucial in automotive, aerospace, and manufacturing industries. Selective heating ensures only targeted areas undergo hardening, preserving the component's core properties. The service significantly enhances component performance and longevity, ensuring reliable operation under demanding conditions. It's an essential process for optimizing the durability and efficiency of various mechanical parts and systems.

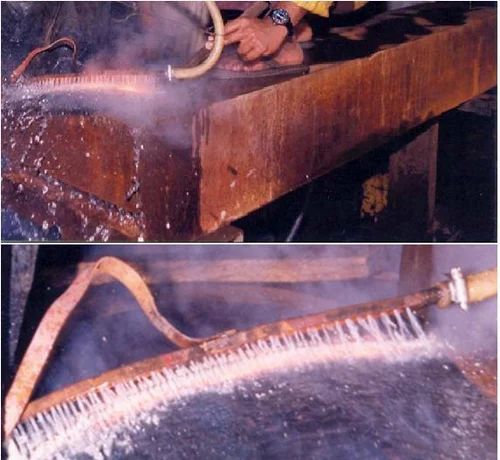

An induction heater for pre and post-weld heat treatment service utilizes electromagnetic induction to heat metal components uniformly. In pre-weld treatment, it aids in stress relief, reducing cracking risks, and enhancing weld quality. Post-weld, it ensures uniform heating for tempering, annealing, or stress relieving, improving material properties and weld integrity. This efficient heating method minimizes distortion and improves productivity, offering a reliable solution for industrial welding operations requiring precise heat treatment.

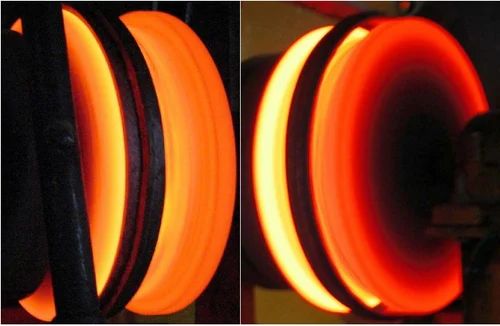

Large diameter induction hardening rolls service employs electromagnetic induction to heat the surface of rolls with substantial diameters, followed by rapid quenching to enhance their properties. This process strengthens the rolls, increasing wear resistance and durability, particularly vital for heavy-duty applications in steel, automotive, and manufacturing industries. By selectively hardening the surface, the rolls maintain their core toughness and structural integrity. This service significantly improves the performance and longevity of large diameter rolls subjected to high loads and extreme conditions.

Pin induction hardening services utilize electromagnetic induction to heat the surface of pins, followed by rapid quenching for enhanced properties. This process strengthens the pins, increasing wear resistance and durability, vital in automotive, aerospace, and machinery sectors. Selective hardening preserves core toughness and structural integrity. The service significantly improves pin performance and lifespan, ensuring reliable operation under heavy loads and harsh conditions. It's essential for safety, efficiency, and reducing maintenance costs in various industrial applications.

Pinion induction hardening service employs electromagnetic induction to heat the surface of pinions, followed by rapid quenching for enhanced properties. This process strengthens the pinions, increasing wear resistance and durability, crucial in automotive, aerospace, and machinery sectors. Selective hardening preserves core toughness and structural integrity. The service significantly improves pinion performance and lifespan, ensuring reliable operation under heavy loads and harsh conditions. It's essential for safety, efficiency, and reducing maintenance costs in various industrial applications.

Shaft induction hardening service involves heating the surface of a shaft through electromagnetic induction, followed by rapid quenching to create a hardened layer. This process enhances the shaft's durability, wear resistance, and strength, particularly in high-stress applications such as automotive components, machinery, and industrial equipment. By selectively hardening only the surface, the core remains relatively unaffected, retaining its toughness. This service is crucial for improving the performance and longevity of shafts subjected to heavy loads and harsh environments.

Smaller diameter induction hardening roll service utilizes electromagnetic induction to heat the surface of smaller diameter rolls, followed by rapid quenching to enhance their properties. This process strengthens the rolls, increasing wear resistance and durability, particularly crucial for precision machining and manufacturing applications. By selectively hardening the surface, the rolls maintain their core toughness and dimensional stability. This service significantly improves the performance and lifespan of smaller diameter rolls, ensuring reliable operation in various industries such as automotive, aerospace, and electronics.

Sprockets induction hardening service utilizes electromagnetic induction to heat the surface of sprockets, followed by rapid quenching for enhanced properties. This process strengthens the sprockets, improving wear resistance and durability, crucial in automotive, machinery, and industrial sectors. Selective hardening preserves core toughness and structural integrity. The service significantly enhances sprocket performance and lifespan, ensuring reliable operation under heavy loads and harsh conditions. It's essential for maintaining efficiency, reducing maintenance costs, and ensuring safety in various drive systems and machinery applications.

Wheels induction hardening service utilizes electromagnetic induction to heat the surface of wheels, followed by rapid quenching for enhanced properties. This process strengthens the wheels, improving wear resistance and durability, crucial in automotive, railway, and heavy machinery sectors. Selective hardening preserves core toughness and structural integrity. The service significantly enhances wheel performance and longevity, ensuring reliable operation under heavy loads and harsh conditions. It's essential for safety, efficiency, and reducing maintenance costs in various transportation and industrial applications.