- View Mobile Number

sales@velinnovative.com

Induction Heating Equipment

Leading Manufacturers, Exporters and Wholesaler of Induction Bearing Heater, Induction Brazing System, Induction Forging Machine, Induction Hardening System, Induction Heater For Pre And Post Weld Heat Treatment, Induction Melting Furnace Equipment, Induction Shrink Fitting System and Custom Designed Solutions for Specialized Applications from Mumbai.

| Business Type | Manufacturer, Exporter, Supplier |

| Application | Industrial Use |

| Type | Bearing Induction Heater |

| Country of Origin | India |

| Temperature Control | 25 – 250 +/- 1°C |

| Safety Interlocks | Soft start to avoid rush of surge current at time of switching,Over temperature of coil trip |

| Residual Magnetism | <2A/cm, Auto De – Magnetization |

| Heating Time | Heating Time is Less Than 2 Minutes |

We are offering a comprehensive range of Microcontroller based Electronic Control, Induction Heater (VEL/BH series) specifically designed and manufactured for mounting of shrink fitting components such as Bearings, inner races, gears, pinons, couplings, etc.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Inverter | IGBT based Inverter |

| Converter | Thyristor based Full bridge Rectifier |

| Incoming Voltage | 415 V/3ph /50 Hz, 3 or 4 wire |

| Output Frequency | 10 – 40 kHz |

| Brazing Tong | Compact Water Cooled Transformer with Flexible Water Cooled Cable |

| Medium of Cooling | Air / Water |

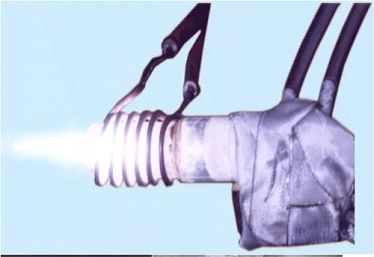

VEL i-Braze Series

VEL i-Braze series comprises of state-of-the-art induction brazing systems designed to meet the evolving demands in the field of metal joining.

It includes an advanced light weight and portable high frequency transformer and joint specific custom designed coils together known as brazing tong. The coils can be easily fitted on and removed from the transformer.

The brazing tong can seamlessly integrate with robotic arms or any automation as per client’s requirements

Standard Features

- Application based customization

- Wide range of output power ratings and frequencies range

- Tolerates abrupt discontinuities in the coil circuit (e.g., sudden insertion, removal, or geometric changes of the workpiece).

- Withstands severe disturbances on incoming power lines.

- Integrates safety-oriented design features to prevent electric shock hazards associated with the brazing tong during operation.

- Features an automatic machine trip mechanism in the event of accidental contact between the brazing tong and the workpiece, ensuring the integrity of both the machine and workpiece.

- Safety Interlocks for Water pressure, temperature, flow, etc.

- Power Factor > 0.90

- Output regulation> 90%

- Intuitive user interface

- Simple and effective indications

TECHNICAL SPECIFICATION

VEL i-Braze System (Type VEL/BR/#) consists of ► Converter ► Inverter ► Microcontroller based Control, Protection & Interlocks ► Output Transformer & Inductor ► Water Cooling & Circulating System (Optional) ► Holding Fixture (Optional) ► XYZ Slide for the Brazing Tong Assembly (Optional)

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Output Frequency | 1-20 kHz |

| Incoming Voltage | 415 V, 3phase, 50 Hz, 4 wire |

| Input Feeder Rating | 800Amps,1600Amps,2400Amps & 3200Amps |

| Application | Industrial |

| Automation Grade | Automatic |

Induction forging process is energy efficient, rapid / instant heating process as it provides superior productivity, consistent quality, flexibility and reliability.

VEL ForgeTech series is specially designed and manufactured for heating metal in forging, rolling, stamping extrusion, upsetting and other forming applications to obtain desired shape in Presses, Bending Machines, Forming machines, etc on turnkey basis. They are designed to heat any dimension of billets, bars, blocks, slabs etc in full or partially in materials as diverse as Steel, Stainless Steel, Brass, Bronze, Aluminium, Copper, Titanium, Silver, etc and their alloys

INDUCTION HEATING POWER SOURCE

Induction Heater , Thyristor / IGBT based, of varying power capacities ranging from 400 kW to 1600 kW consisting of Inverter modules auto tuned to Resonant Frequency ranging from 1 to 20kHz, incorporating Microcontroller (µC) based electronic controls, Protection/Trip circuits, Interlocks etc, Output Matching Transformer, Inductor Assemblies etc.

CONTROL AND FEEDBACK SYSTEM

PLC based control system & SCADA for automated system & process. All alarms generated and machine / process parameters displayed / controlled from HMI on Control Panel / SCADA.

Non-contact pyrometers are used to measure the part temperature to achieve precision temperature control, to maintain temperature consistency, feedback for hold modes, option to reject job for over/under job temperatures etc.

HEATING STATION

The induction coil is completely contained within the steel shell and is isolated from the job with a refractory coating. There is no chance of hot slag or other materials from the furnace contaminating the room.

LOADING/ UNLOADING & FEEDING SYSTEM

Semi-Automated/ Fully Automated job loading/unloading facility are available, such as Vibratory, magazine, step, or bowl feeders, V-flight and other conveyor feeders to move billets into drive position, Pneumatic or hydraulic horizontal pusher, tractor drive, pinch roller drive or walking beam arrangement for moving job through the inductor, High-speed conveyors to rapidly deliver the hot job to press operator or robot pick up point, etc

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Inverter | IGBT based Inverter |

| Converter | Thyristor based Full bridge Rectifier |

| Incoming Voltage | 415 V, 3phase, 50 Hz, 4 wire |

| Output Power | 100 amps,200 amps,400 amps,& 800 amps |

| Output Frequency | 1-100 kHz (as per job requirement) |

| Output Voltage | 0 – 400 V |

| Body Material | Mild Steel |

The VEL HardTech series represents cutting-edge induction hardening, annealing, and tempering systems tailored to meet the evolving needs of the heat treatment industry.

We offer complete turnkey solutions that include an advanced Induction Power Source, CNC/PLC control automation, high-frequency transformer, and custom-designed coils tailored for specific jobs. Our solutions also feature job-specific scanning (horizontal or vertical), single-shot fixtures, and rotary or indexing tables. They seamlessly integrate with semi or fully automated job loading and unloading facilities, ensuring that the system fulfils your hardening requirements effectively.

Features:

- Manual and automated program settings with multiple pre-programmed recipes.

- Intuitive touch panel interface with comprehensive process monitoring features.

- Quick connect coil system facilitates easy replacement of induction coils.

- Efficient load/unload and part centering system for manual or automated operations.

- Designed for in-line integration, ensuring short lead times and seamless workflow.

- Reliable mechanical solutions ensure high system availability and productivity.

- Precise process control leads to excellent results and increased productivity.

- Energy-efficient power supply unit (>95% efficiency) reduces energy costs.

- Flexible design accommodates a wide range of part sizes for versatility.

- Modular unit for easy servicing and maintenance, minimizing downtime.

Technical specification:

The Induction Hardening System (VEL/IH Series) is specially designed for Induction Hardening of components on turnkey basis complete with > Induction Power Source > CNC/PLC based servo motor driven Vertical/Horizontal Scanner > Water circulating & Cooling system and Quenching system > Semi-Automated/ Fully Automated job loading/unloading facility (optional)

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Automatic Grade | Automatic |

| Cooling Coil | Air & Water |

| Heating Rate | 1-50⁰C/min |

| Material | Mild Steel |

| Output Power | 20kW ,40kW,50kW ,100kW & 200kW |

| Application | Pre-Heating & Post Weld Heat Treatment |

The VEL PH/PW series provides a highly versatile tool for preheating, stress relieving, hydrogen bake out and post weld heat treat in a variety of pipe diameters and flat plate.

Features:

- Designed for continuous heating operation

- Equipped with rugged heavy duty components to tolerate harsh working conditions

- Very Compact and portable (could be easily mounted on any trailer / trolley & moved by forklift / crane)

- All safety trips / interlocks incorporated including sensing the temperature of critical power components of the equipment

- Efficiency of the power source is better than 95%

- Low Voltage design makes it very safe to use at site

- Inductors are specifically designed keeping in mind ease of operation required.

- Thermal Profile Controller, Data Logger & Paper Chart Temperature Recorder is integrated as required.

- Provides uniform rapid heating in plate and pipe applications

- Reduces set-up time and time -to temperature

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Mild Steel |

| Driven Type | Electric |

| Automatic Grade | Automatic |

| Application | Melting Furnace |

| Country of Origin | India |

| Power Regulation | (10 – 100%) |

| Temperature Controller | Works with a Thermocouple Probe or Optional Ir Pyrometer. |

| Control Type | Automatic / Manual tilting control. |

VEL MeltPro series is a comprehensive range of furnaces for melting all non ferrous metals and precious metals like silver, gold etc.

This melting equipment has a long life and provides an accurate temperature measurement.

Features:

- Power regulation (10 – 100%)

- Advanced software driven solid state converters.

- Temperature controller – works with a thermocouple probe or optional IR pyrometer.

- Fast acting electronic interlocks for safe and reliable operation.

- Automatic / Manual tilting control.

- Custom models with different capacities can be designed.

Techincal Specification:

VEL MeltPro serries consists of ►Converter ► Inverter ► Control, Protection & Interlocks► Output Transformer ►Coil / Furnace► Water Cooling & Circulating System.

| Business Type | Manufacturer, Exporter, Supplier |

| Power Factor | > 0.90 |

| Output Frequency | 2-20 kHz |

| Time Control | 0-9.9 mins |

| Maximum Temperature | 250°C (max) |

| Power Control | Continuously Variable from 0-100%. Soft Start, Auto Ramping |

| Output Power | 5 kW,20 kW,40 kW& 80 kW |

| Machine Material | Mild Steel |

| Automation Grade | Semi-Automatic |

| Power Source | Induction |

VEL Extract Ease series, a cutting-edge solution at the forefront of technology, intelligent microcontroller based electronic control, solid state IGBT based high frequency Induction Heater, specifically designed and manufactured for dismounting and mounting of shrink fit components like bearings, inner races, coupling, pinions, gears, sleeves, throwers, retaining collar etc.

Salient Features

- Highly efficient and fast heating compared to conventional low frequency systems.

- Air cooled system, so no need to handle water or any coolant

- Flexible air cooled coil to suit different types of job making it versatile and user friendly

- Compatible with rigid Induction Coils (weight less than 5 kgs) for continuous production operations.

- No magnetization at high frequency hence no need for demagnetization cycle.

- Built-in safeguards, including Over Voltage, Over Current, Coil Winding Temperature, and Device Temperature trips, etc

| Business Type | Manufacturer, Exporter, Supplier |

| Power Source | Electric |

| Application | Industrial Use |

| Country of Origin | India |

| Voltage | 460V |

| Frequency | 0.5KHz To 10KHz |

| Body Material | Mild Steel |

Plasma is a unique state of matter consisting of unbound positive and negative particles, electrically neutral overall. It lacks a defined shape unless confined. Generating plasma involves applying an electrical field to a gas, causing electrons to break free from their orbits around nuclei, creating ions and free-flowing electrons. This imparts key properties like electrical conductivity, magnetic field generation, and responsiveness to external electromagnetic fields.

Sustaining plasma requires continuous energy input, making induction an ideal method for this purpose. Industrial applications of plasma include welding, metal cutting, surface treatments such as plasma spray coating, and etching in microelectronics.