- View Mobile Number

sales@velinnovative.com

Water Spray System for Cement Plants

Leading Manufacturers, Exporters and Wholesaler of Cement Mill Water Spray System and Grate Cooler Water Spray System from Mumbai.

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Automatic Grade | Automatic |

| Application | Industrial |

| Type | Water Spray System |

| Country of Origin | India |

| Material | Mild Steel |

During the process of finish grinding of clinker, lot of heat is generated inside the cement mill. The heat generated in excess has to be dissipated so that mill discharge temperature is kept at a desired level (around 90-120°C) to prevent the deterioration of the quality of cement. The increase in temperature beyond 125°C leads to dehydration of gypsum which changes the property of setting of cement. The decrease in temperature below 90°C leads to wet clogging of gypsum and the cement strength is affected.

Internal water cooling in a cement mill serves to maintain the mill outlet temperature constant at preset values.

VEL Cement Mill Water Spray System is the advanced method of temperature control in cement mills which results in enhanced cement quality.

Application

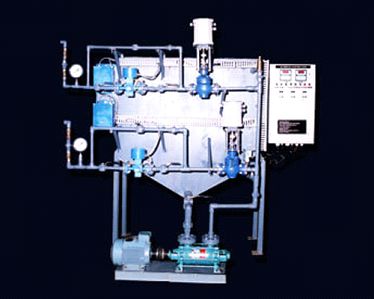

VEL Cement Mill Water Spray System comprises of complete set of pumps, valves, spray nozzles. instruments etc & all relevant accessories, assembled as one unit making it user-friendly and easy to install.

Water Cooling in the Cement Mill is accomplished by injecting and evaporating water at the outlet / inlet end of the mill. The water vapour is removed from the mill together with the ventilation air, which must be so ample that the temperature does not drop below the dew point anywhere in the pipes, dedusting filter, etc after the mill.

The system ensures precise control of temperature in both the chambers of cement mill by regulating the volume of injected water through motorised control valves. The design of the injection nozzles and the compressed air used for atomization gives a very good turn down ratio in the entire range of water flow regulation. When the water injection is disconnected, compressed air purging keeps the injection nozzles clean. The system may be interfaced and operated through your existing PLC/DCS or may be provided with a standalone control panel.

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Condition | New |

| Automatic Grade | Automatic |

| Application | Industrial |

| Type | Water Spray System |

| Weight | 200-300kg |

| Country of Origin | India |

| Material | Mild Steel |

VEL Cooler water spray system comprises of complete set of skid mounted pumping & valve train system along with spray nozzles & relevant accessories. All necessary instruments, control valves etc are provided. All closed loop controls, sequence of operation, alarms & Safety interlocks are provided. The system may be interfaced to your existing PLC/DCS or may be provided with a standalone control panel.

DESIGN CRITERIA

The purpose or application, dimensions of the Grate Cooler, the height of the clinker bed, the overall gas flow, the gas temperature, the clinker temperature profile, number of nozzles needed and the height at which the lances are to fixed in the cooler compartment, the degree of cooling required put together determines the type of is spray system to be used,that is:

Compressed air atomized water spray system

Spillback water spray system

Fogjet / Multicone water spray system

Flatjet water spray system

Application

In Cement Industries, VEL Grate Cooler Water Spray System is used for cooling the vent gas for any of these purposes:

To increase the efficiency of ESP by reducing fugitive dust emission.

To reduce the power consumption of the vent outlet fan.

To maintain a slightly more negative pressure at vent outlet thus contributing in reducing fugitive emission.

To reduce the temperature so that the upstream conveying equipments could be designed for lower temperatures thus reducing the capital cost.

To cool the clinker directly so that the inlet temperature to cement mill is within controllable limits.

To control the depth of the clinker bed both to avoid grate burn-out due to low bed depth, and to avoid stalling the cooler fans due to excessive bed depth.

To limit fluctuations in the secondary air temperature as this can upset the kiln temperature profile and adversely affect clinker quality.

Principle Of Operation

In VEL Grate Cooler Water Spray System, the temperature of the stream of gas / clinker is cooled in three stages:

Heating of the injected liquid to the boiling point temperature corresponding to the system pressure.

Conversion of part of the liquid into a gaseous state by evaporation of the liquid.

Superheating of the evaporated liquid.

We can also provide Grate Cooler Water Spray System especially for Direct Cooling of Clinker bed. This is normally required when the cooler is operated above its designed capacity.

We design, manufacture, supply to achieve your ultimate goal.