- View Mobile Number

sales@velinnovative.com

Custom Designed Solutions for Specialized Applications

Leading Manufacturers, Exporters and Wholesaler of Induction Heat-Exchanger Tube Detacher, Induction Plasma Heater and Magnetic Levitation Melting from Mumbai.

| Business Type | Manufacturer, Exporter, Supplier |

| Shape | Round |

| Application | Industrial Use |

| Feature | Durable, Optimum Quality, Rust Proof, Supreme Finish |

| Type | Sheet Tube |

| Country of Origin | India |

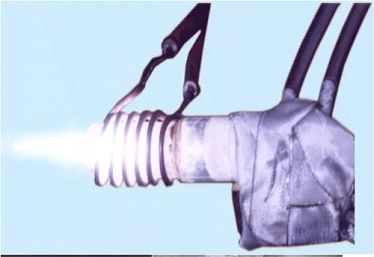

| Finshing | Polished |

The roll joints on the tube sheet of shell and tube heat exchangers, formed using an expander tool, play a critical role in efficient heat transfer. We have pioneered and successfully implemented an innovative Induction shock heating process specifically tailored for this application in nuclear reactors, a feat unmatched by others. This groundbreaking technology holds potential for detaching tubes in boilers, power plants, steam generators, and various industrial systems, offering unparalleled efficiency and reliability in maintenance operations.

| Business Type | Manufacturer, Exporter, Supplier |

| Power Source | Electric |

| Application | Industrial Use |

| Country of Origin | India |

| Voltage | 460V |

| Frequency | 0.5KHz To 10KHz |

| Body Material | Mild Steel |

Plasma is a unique state of matter consisting of unbound positive and negative particles, electrically neutral overall. It lacks a defined shape unless confined. Generating plasma involves applying an electrical field to a gas, causing electrons to break free from their orbits around nuclei, creating ions and free-flowing electrons. This imparts key properties like electrical conductivity, magnetic field generation, and responsiveness to external electromagnetic fields.

Sustaining plasma requires continuous energy input, making induction an ideal method for this purpose. Industrial applications of plasma include welding, metal cutting, surface treatments such as plasma spray coating, and etching in microelectronics.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Corrosion Resistance | Yes |

| Usage/Application | Industrial |

| Automation Grade | Automatic |

| Output Current | 0-100 A |

| Surface Finishing | Polished |

Induction levitation melting is an advanced metallurgical process that uses electromagnetic induction to suspend and heat a conductive material, typically a metal, without physical contact. This method is unique because it allows for precise control over melting and refining processes while minimizing contamination risks. Induction is preferred for levitation melting due to its efficiency, uniform heating, and suitability for handling reactive materials. Applications of induction levitation melting include producing high-purity alloys, refining exotic metals, creating specialty materials for aerospace applications, and conducting research in materials science.