- View Mobile Number

sales@velinnovative.com

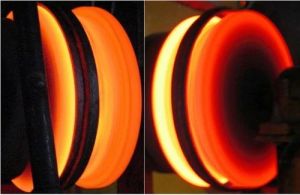

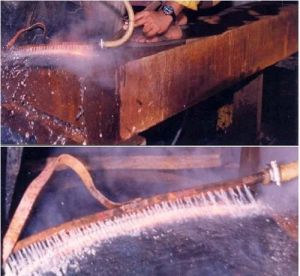

Pin induction hardening services utilize electromagnetic induction to heat the surface of pins, followed by rapid quenching for enhanced properties. This process strengthens the pins, increasing wear resistance and durability, vital in automotive, aerospace, and machinery sectors. Selective hardening preserves core toughness and structural integrity. The service significantly improves pin performance and lifespan, ensuring reliable operation under heavy loads and harsh conditions. It's essential for safety, efficiency, and reducing maintenance costs in various industrial applications.

Looking for "Pin Induction Hardening Services" ?

Piece